Hydraulic Design

The publication “CPDA – Bedding construction and flow capacity of vitrified clay pipelines” will assist the drainage designer to size pipelines hydraulically.

It is important that drainage runs are correctly sized so that the flow is discharged off the site in an effective and efficient manner. The following notes should help you design drainage to a good standard.

Undersized drains result in the flow running at too high a level with serious risk of surcharge at times of heavy rainfall. In addition the build up of potentially dangerous sewer gases could occur as a result of inadequate ventilation.

Oversized drains reduce the depth of flow in the system causing settlement of solids, silt or grit which could result in blockages. It is therefore to be avoided in all foul water systems but is considered acceptable on some surface water systems and in certain instances is used as a detention tank to store flood water and help prevent problems further downstream.

There are various methods of determining flow characteristics of drains. This section shows ways of calculating hydraulic flow characteristics for surface, foul and combined drains using methods detailed in BS EN752 which is satisfactory for most drainage systems. It also outlines the importance of choosing the correct pipe sizes, gradients and speed of flow for drainage systems.

It is normal practice to calculate surface and foul water drainage systems separately. However, as a Designer you would also be expected to keep an eye on both systems to avoid potential crossovers, or to ensure that one system is not getting too deep whilst the other remains shallow.

Surface Water

BS EN752 includes the ‘flat rate of rainfall’ method for assessing the peak discharge of surface water and is suitable for drains that do not exceed 200m in length. This assumes a flat rate of rainfall of 50mm/hour. This rainfall intensity is regarded as satisfactory by most regulatory bodies, however some areas of the country are susceptible to heavy rainfall, or may not tolerate surface ponding and therefore a different figure (e.g. 75mm/hour) may be required by the authority. This higher value may also be applied to areas deemed to need a higher level of protection, such as commercial premises. The whole of the rainfall on impervious areas should be assumed to reach the drain, whilst all pervious areas should be disregarded from the equation.

Using the ‘Surface Water Flow Calculation Sheet’ in this section. The following sequence should be followed to calculate the correct pipe sizing and gradients:

- Select drain run to be calculated. (eg. SWMH2 – SWMH3)

- Calculate the effective roof area of all buildings that enter this drain run and enter the total into column B.

- Multiply ‘B’ by the rainfall intensity (normally 50mm/hour) and divide by 3600 to convert the flow rate to l/s. Enter this local into column C.

- Calculate the total impervious paved area being served by this drain and enter this figure into column D.

- Multiply ‘D’ by the rainfall intensity as above and enter this into column E.

- Add C to E and enter total into F.

- Add ‘F’ to the sum of any other drainage runs that enter this run where applicable (eg. SWMH1 – SWMH2) and enter the value into column G.

- Using the ‘Surface Water Flow Tables’ in this section, find a value of ‘Discharge’ that is larger than the total obtained in column G of the calculation sheet.

- The pipe size is shown on the column heading. Ensure that the pipe size is at least the same size as all preceding drainage runs.

- The minimum pipe gradient is shown in the left hand column. Ensure that the gradient obtained is not too steep to prevent connection to the outfall.

- Where the discharge figure obtained falls within the shaded grey area of the table, we recommend that the pipe size and/or gradient are increased.

Soakaway Design

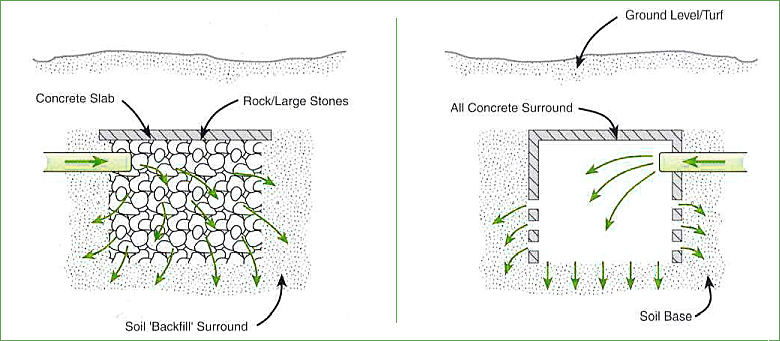

Where the surface water drains cannot be discharged to a sewer, ditch or watercourse, it may be necessary to discharge to a soakaway. It is often more economical to use soakaways because pipe sizes are generally kept quite small, however they can only be considered in permeable ground conditions (such as sand, silt, chalk, etc.) and should be positioned in areas where stability and support to foundations of adjacent structures can be maintained. Where any doubt exists as to the suitability of the ground, it may be necessary to obtain permeability figures by ground investigation. This should be carried out by a recognised Soils Engineer or Geologist who will then recommend on the suitability of soakaways. Further information is given in BRE Digest 365 and in BS 6297.

Modern soakaways are generally constructed of pre-cast concrete rings with holes in them to allow water to escape. Other soakaways may take the form of land drains (such as perforated city pipe), traditional brick built pits jointed in honeycomb bond, or a combination of the above.

The hydraulic design of pipework is carried out as shown above, but because pipe runs are kept to a minimum when soakaways are utilised, there is normally very little pipe sizing to take account of. The volume of water to be stored does require calculation. BS EN752 specifies a storage volume sufficient for a minimum of 20mm of rainfall over the area to be drained, based on 100% impermeability for all hardstanding areas.

A simple equation to calculate the storage capacity of a soakaway is given below:

Q = 0.02 A

where

Q = the capacity (in m3)

A = the area to be drained (in m2)

Once the storage capacity has been calculated, the following table may be used to calculate the size and effective depth of the soakaway. The table is based on the above formula and uses standard sized pre-cast concrete rings.

NB. Effective Depth is measured from the invert of the lowest incoming pipe to the base of the soakaway. A soakaway filled with gravel, hardcore, etc. has less volume than an un-filled pit, so the value obtained from the table below will have to be adjusted.

Effective depth (m) |

Soakaway Diameter (mm) |

|||

| 900 | 1050 | 1200 | 1350 | |

| 0.50 | 0.32 m³ | 0.43 m³ | 0.57 m³ | 0.72 m³ |

| 0.75 | 0.48 m³ | 0.65 m³ | 0.85 m³ | 1.07 m³ |

| 1.00 | 0.64 m³ | 0.87 m³ | 1.13 m³ | 1.43 m³ |

| 1.25 | 0.80 m³ | 1.08 m³ | 1.41 m³ | 1.79 m³ |

| 1.50 | 0.95 m³ | 1.30 m³ | 1.70 m³ | 2.15 m³ |

| 1.75 | 1.11 m³ | 1.52 m³ | 1.98 m³ | 2.50 m³ |

| 2.00 | 1.27 m³ | 1.73 m³ | 2.26 m³ | 2.86 m³ |

Ground Water Drainage

Drainage of groundwater may be considered for a number of reasons such as:

- to increase ground stability;

- to avoid flooding;

- to alleviate subsoil water pressures;

- to prevent foundation damage;

- to reduce risk of frost heave.

Perforated clay pipes provide an economic and efficient solution for the collection of excess ground water to prevent the above problems. It is normal to lay perforated pipes with ‘holes up’ in collector drains and ‘holes down’ in branch drains.

A typical flow rate of 5 Litres per Hectare per Second for normal ground conditions, but higher flow rates should be used where surfaces have high porosity. Pipe sizes and gradients can be calculated accordingly, paying attention to the fact that only 2/3’s capacity of the pipe can be used to carry the flow because of the position of the holes within the pipe.

Foul Drainage

BS EN752 adopts the Discharge Unit method of design which is based on the probability theory to estimate maximum peak flows from appliances. It assumes that only a proportion of appliances will be in use at any one time and that appliances on a factory, school, etc. would be used more frequently than in domestic installations. For this reason discharge units (DU) are given higher values in congested and commercial use than they are for domestic. Certain appliances are allocated a flow rate rather than DU because the flow from these is very small as indicated in the table below.

The Discharge Unit Method is normally only used for building drainage, because it could result in an over sizing of pipes in excessively long drains or sewers.

Calculation of Wastewater Flows for Drain Systems

Typical frequency factors (kDU)

Type of Building |

kDU |

| Dwelling, guesthouse, office (intermittent use) | 0.5 |

| Hospital, school, restaurant, hotel (frequent use) | 0.7 |

| Toilets and/or shower open to the public (congested use) | 1.0 |

| Laboratory buildings (special use) | 1.2 |

Typical values of discharge units (DU)

Type of Appliance |

DU |

| Washbasin, shower | 0.3 to 0.6 |

| Urinal | 0.3 to 0.8 |

| Bath, kitchen sink | 0.8 to 1.3 |

| Dishwasher | 0.2 to 0.8 |

| Household washing machine | 0.5 to 0.8 |

| Commercial washing machine | 1.0 to 1.5 |

| WC’s (4.0 to 9.0l cistern) | 1.2 to 2.5 |

| Floor drains (DN50 to DN100) | 0.6 to 2.0 |

| Where no specific information is available, the higher value must be used |

The following empirical equation (1) may be used:

Q = kDU √∑DU

Q is the wastewater design flow rate, in litres per second

kDU is the frequency factor, dimensionless

DU is discharge unit (a characteristic value of the rate of wastewater outflow of a sanitary appliance)

Foul drainage is designed to 0.7 capacity to prevent trap siphonage and to maintain ventilation.

Using the ‘Foul Water Flow Calculation Sheet’ the following sequence should be followed to calculate correct pipe sizing and gradients:

- Select drain run to be calculated. (E.g. FWMH2 – FWMH3).

- On domestic installations, add together the number of dwellings with drainage entering this pipe run and multiply this figure by 3 DU. Enter the result into column C.

OR

- On commercial and congested installations, calculate the DU value of all appliances and enter this total into column C.

- Add this figure to the sum of all other DU’s entering the drain from preceding drain runs (E.g. FWMH1 – FWMH2) and enter into column D.

- Using equation (1) calculate flow and enter the total into column E.

- Using the ‘Flow Water Flow Table’, find a value of ‘Discharge’ that is larger than the total obtained in column E of the calculation sheet and enter this value into column J.

- Complete columns F, G and H that corresponds to that discharge.

- Complete the equation in column K and from the table of ‘Proportional Velocities and Discharges in pipes running Part Full’, enter values of proportional velocity and proportional depth into columns L and M respectively.

- If the proportional depth entered in column M is greater than 0.7, increase the proposed gradient and/or make the pipe size larger, until the proportional depth result is less than 0.7.

- Multiply the results of column H and L. Enter this total into column N. If the result is less than 0.7m/s re-calculate using steeper gradients and/or a smaller pipe. Ensure that the pipe size chosen is at least the same size as all preceding drainage runs.

- Ensure that the gradient chosen is not too steep to prevent connection to the outfall, and the pipe size is not too large to connect to any existing foul or combined sewer.

Combined Drainage

It may be necessary to install surface and foul water drains separately even where a site is being served by an existing combined sewer. This should be confirmed with relevant authorities prior to designing the drainage.

When a one pipe system is installed, it is important that all surface water fittings such as rainwater pipes or road gullies are trapped so that foul gases cannot cause nuisance.

A combined drain should be capable of accepting peak surface and foul water flows. It is also good design practice to ensure that self cleansing velocity (0.75l/s) is achieved when only foul water flow is entering the drain (ie. When there is no rain). It may be easier to complete both surface and foul water sheets prior to completing the combined flow calculation sheet.

The optimum method of calculating drainage flow rates is detailed below: Use the ‘Combined Flow Calculation Sheet in this section.

- Select drain run to be calculated. (E.g. COMBINED 2 – COMBINED 3).

- Determine the cumulative surface water flow entering this drain by completing the surface water flow calculation sheet as detailed previously and enter the total into column B of the combined sheet.

- Determine the total and cumulative foul water discharge units (DU) entering this drain by completing the foul water flow calculation sheet as detailed previously and enter the total into columns C and D of the combined sheet.

- Using equation (1) to convert DU into flow rates enter a total into column E of the combined sheet.

- Add B to E and enter total into column F.

- Using the ‘Foul Water Flow Table’ below, find a value of ‘Discharge’ that is larger than the total obtained in column F of the calculation sheet and enter this value into column K.

- Complete columns G, H and J that correspond to that discharge.

- Complete the equation in column L and from the table of ‘Proportional Velocities and Discharges in pipes running Part Full in this section, enter values of proportional velocity and proportional depth into columns M and N respectively.

- If the proportional depth entered in column N is greater than 0.7, increase the proposed gradient and/or make the pipe size larger, until the proportional depth result is less than 0.7.

- Multiply the results of columns J and M. Enter this total into column P. If the result is less than 0.7m/s re-calculate using steeper gradients and/or a smaller pipe. Ensure that the pipe size chosen is at least the same size as all preceding drainage runs.

- Ensure that the gradient chosen is not too steep to prevent connection to the outfall and the pipe size is not too large to connect to any existing foul or combined sewer.

Surface Water Flow Table (For DN100-DN500)

PIPE FLOWING FULL Ks VALUE = 0.6mm

| ks value 0.6mm | Pipe Size (mm) | |||||||||||||||

| DN 100 | DN 150 | DN 225 | DN300 | DN 375 | DN 400 | DN 450 | DN500 | |||||||||

| GRAD | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS |

| m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | |

| 1/10 | 2.47 | 19.41 | 3.22 | 56.87 | 4.18 | 166.02 | 5.01 | 354.36 | 5.77 | 637.40 | 6.01 | 755.25 | 6.47 | 1029.13 | 6.91 | 1357.06 |

| 1/20 | 1.75 | 13.73 | 2.28 | 40.21 | 2.95 | 117.39 | 3.54 | 250.57 | 4.08 | 450.71 | 4.25 | 534.04 | 4.58 | 727.71 | 4.89 | 959.58 |

| 1/30 | 1.43 | 11.21 | 1.86 | 32.83 | 2.41 | 95.85 | 2.89 | 204.59 | 3.33 | 368.00 | 3.47 | 436.04 | 3.74 | 594.17 | 3.99 | 783.50 |

| 1/40 | 1.24 | 9.71 | 1.61 | 28.44 | 2.09 | 83.01 | 2.51 | 177.18 | 2.89 | 318.7 | 3.01 | 377.62 | 3.24 | 514.57 | 3.46 | 678.53 |

| 1/50 | 1.11 | 8.68 | 1.44 | 25.43 | 1.87 | 74.25 | 2.24 | 158.48 | 2.58 | 285.06 | 2.69 | 337.76 | 2.89 | 460.24 | 3.09 | 606.89 |

| 1/60 | 1.01 | 7.92 | 1.31 | 23.22 | 1.70 | 67.78 | 2.05 | 144.67 | 2.36 | 260.22 | 2.45 | 308.33 | 2.43 | 420.14 | 2.82 | 554.02 |

| 1/70 | 0.93 | 7.34 | 1.22 | 21.50 | 1.58 | 62.75 | 1.89 | 133.94 | 2.18 | 240.92 | 2.27 | 285.46 | 2.45 | 388.98 | 2.61 | 512.92 |

| 1/80 | 0.87 | 6.86 | 1.14 | 20.11 | 1.48 | 58.70 | 1.77 | 125.29 | 2.04 | 225.36 | 2.12 | 267.02 | 2.29 | 363.85 | 2.44 | 479.79 |

| 1/90 | 0.82 | 6.47 | 1.07 | 18.96 | 1.39 | 55.34 | 1.69 | 118.12 | 1.92 | 212.49 | 2.00 | 251.75 | 2.16 | 343.04 | 2.3 | 542.35 |

| 1/100 | 0.78 | 6.14 | 1.02 | 17.98 | 1.32 | 52.50 | 1.59 | 112.06 | 1.82 | 201.56 | 1.90 | 238.83 | 2.05 | 325.44 | 2.19 | 429.14 |

| 1/100 |

0.75 |

5.85 |

0.97 | 17.15 | 1.26 | 50.06 | 1.51 | 106.84 | 1.74 | 192.18 | 1.81 | 227.72 | 1.95 | 310.29 | 2.08 | 409.17 |

| 1/120 |

0.71 |

5.60 |

0.93 | 16.42 | 1.21 | 47.93 | 1.45 | 102.29 | 1.67 | 184.00 | 1.73 | 218.02 | 1.78 | 297.08 | 2.00 | 391.75 |

| 1/130 |

0.69 |

5.38 |

0.89 | 15.77 | 1.16 | 46.05 | 1.39 | 98.28 | 1.60 | 176.78 | 1.67 | 209.47 | 1.79 | 285.43 | 1.92 | 376.38 |

| 1/140 |

0.66 |

5.19 |

0.86 | 15.20 | 1.12 | 44.37 | 1.34 | 94.74 | 1.54 | 17035 | 1.61 | 201.85 | 1.73 | 275.05 | 1.85 | 362.69 |

| 1/150 |

0.64 |

5.01 |

0.83 | 14.68 | 1.08 | 42.87 | 1.29 | 91.50 | 1.49 | 164.58 | 1.55 | 195.00 | 1.67 | 265.72 | 1.78 | 350.39 |

| 1/175 |

0.59 |

4.64 |

0.77 |

13.59 |

1.00 | 39.69 | 1.20 | 84.71 | 1.38 | 152.37 | 1.44 | 180.54 | 1.55 | 246.01 | 1.65 | 324.40 |

| 1/200 |

0.55 |

4.34 |

0.72 |

12.72 |

0.93 | 37.12 | 1.12 | 79.24 | 1.29 | 142.53 | 1.34 | 168.88 | 1.45 | 230.12 | 1.55 | 303.45 |

| 1/225 |

0.52 |

4.09 |

0.68 |

11.99 |

0.88 | 35.00 | 1.06 | 74.71 | 1.22 | 134.38 | 1.27 | 159.22 | 1.36 | 216.96 | 1.46 | 286.09 |

| 1/250 |

0.49 |

3.88 |

0.64 |

11.37 |

0.84 |

33.20 |

1.00 | 70.87 | 1.15 | 127.48 | 1.20 | 151.05 | 1.29 | 205.83 | 1.38 | 271.41 |

| 1/275 |

0.47 |

3.70 |

0.61 |

10.84 |

0.80 |

31.66 |

0.96 | 67.57 | 1.10 | 121.55 | 1.15 | 144.02 | 1.23 | 196.25 | 1.32 | 258.78 |

| 1/300 |

0.45 |

3.54 |

0.59 |

10.38 |

0.76 |

30.31 |

0.92 | 64.70 | 1.05 | 116.37 | 1.10 | 137.89 | 1.18 | 187.89 | 1.26 | 247.76 |

THESE GRADIENTS ARE NOT RECOMMENDED

Foul Water Flow Table (For DN100-DN500)

PIPE FLOWING FULL Ks VALUE = 1.5mm

| ks value 1.5mm | Pipe Size (mm) | |||||||||||||||

| DN 100 | DN 150 | DN 225 | DN 300 | DN 375 | DN 400 | DN 450 | DN 500 | |||||||||

| GRAD | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS | VEL | DIS |

| m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | m/s | l/s | |

| 1/10 | 2.12 | 16.64 | 2.79 | 49.24 | 3.65 | 145.00 | 4.40 | 311.20 | 5.09 | 562.00 | 5.31 | 666.65 | 5.72 | 910.19 | 6.12 | 1202.28 |

| 1/20 | 1.50 | 11.77 | 1.97 | 34.82 | 2.58 | 102.53 | 3.11 | 220.05 | 3.60 | 397.40 | 3.75 | 471.39 | 4.05 | 643.60 | 4.33 | 850.14 |

| 1/30 | 1.22 | 9.61 | 1.61 | 28.43 | 2.11 | 83.71 | 2.54 | 179.67 | 2.94 | 324.47 | 3.06 | 384.89 | 3.30 | 525.50 | 3.54 | 694.14 |

| 1/40 | 1.06 | 8.32 | 1.39 | 24.62 | 1.82 | 72.50 | 2.20 | 155.60 | 2.54 | 281.00 | 2.65 | 333.32 | 2.86 | 455.10 | 3.06 | 601.14 |

| 1/50 | 0.95 | 7.44 | 1.25 | 22.02 | 1.63 | 64.84 | 1.97 | 139.17 | 2.28 | 251.34 | 2.37 | 298.13 | 2.56 | 407.05 | 2.74 | 537.67 |

| 1/60 | 0.86 | 6.79 | 1.14 | 20.10 | 1.49 | 59.19 | 1.80 | 127.05 | 2.08 | 229.44 | 2.17 | 272.16 | 2.34 | 371.59 | 2.50 | 490.83 |

| 1/70 | 0.80 | 6.29 | 1.05 | 18.61 | 1.38 | 54.80 | 1.66 | 117.62 | 1.92 | 212.42 | 2.01 | 251.97 | 2.16 | 344.02 | 2.31 | 454.42 |

| 1/80 | 0.75 | 5.88 | 0.99 | 17.41 | 1.29 | 51.26 | 1.56 | 110.03 | 1.80 | 198.70 | 1.88 | 235.70 | 2.02 | 321.80 | 2.16 | 425.07 |

| 1/90 |

0.71 |

5.55 |

0.93 | 16.41 | 1.22 | 48.33 | 1.47 | 103.73 | 1.70 | 187.33 | 1.77 | 222.22 | 1.91 | 303.40 | 2.04 | 400.76 |

| 1/100 |

0.67 |

5.26 |

0.88 | 15.57 | 1.15 | 45.85 | 1.39 | 98.41 | 1.61 | 177.72 | 1.68 | 210.82 | 1.81 | 287.83 | 1.94 | 380.19 |

| 1/110 |

0.64 |

5.02 |

0.84 | 14.85 | 1.10 | 43.72 | 1.33 | 93.83 | 1.53 | 169.45 | 1.60 | 201.00 | 1.73 | 274.43 | 1.85 | 362.50 |

| 1/120 |

0.61 |

4.80 |

0.80 | 14.21 | 1.05 | 41.86 | 1.27 | 89.84 | 1.47 | 162.24 | 1.53 | 192.44 | 1.65 | 262.75 | 1.77 | 347.07 |

| 1/130 |

0.59 |

4.61 |

0.77 | 13.66 | 1.01 | 40.21 | 1.22 | 86.31 | 1.41 | 155.87 | 1.47 | 184.89 | 1.59 | 252.44 | 1.70 | 333.45 |

| 1/140 |

0.57 |

4.45 |

0.74 | 13.16 | 0.97 | 38.75 | 1.18 | 83.17 | 1.36 | 150.20 | 1.42 | 178.17 | 1.53 | 243.26 | 1.64 | 321.32 |

| 1/150 |

0.55 |

4.30 |

0.72 | 12.71 | 0.94 | 37.44 | 1.14 | 80.35 | 1.31 | 145.11 | 1.37 | 172.13 | 1.48 | 235.01 | 1.58 | 310.43 |

| 1/175 |

0.51 |

3.98 |

0.67 |

11.77 |

0.87 | 34.66 | 1.05 | 74.39 | 1.22 | 134.34 | 1.27 | 159.36 | 1.37 | 217.58 | 1.46 | 287.40 |

| 1/200 |

0.47 |

3.72 |

0.62 |

11.01 |

0.82 | 32.42 | 0.98 | 69.59 | 1.14 | 125.67 | 1.19 | 149.07 | 1.28 | 203.53 | 1.37 | 268.84 |

| 1/225 |

0.45 |

3.51 |

0.59 |

10.38 |

0.77 | 30.57 | 0.93 | 65.61 | 1.07 | 118.48 | 1.12 | 140.54 | 1.21 | 191.89 | 1.29 | 253.46 |

| 1/250 |

0.42 |

3.33 |

0.56 |

9.85 |

0.73 |

29.00 |

0.88 | 62.24 | 1.02 | 112.40 | 1.06 | 133.33 | 1.14 | 182.04 | 1.22 | 240.46 |

| 1/275 |

0.40 |

3.17 |

0.53 |

9.39 |

0.70 |

27.65 |

0.84 | 59.34 | 0.97 | 107.17 | 1.01 | 127.12 | 1.09 | 173.57 | 1.17 | 229.27 |

| 1/300 |

0.39 |

3.04 |

0.51 |

8.99 |

0.67 |

26.47 |

0.80 | 56.82 | 0.93 | 102.61 | 0.97 | 121.71 | 1.04 | 166.18 | 1.12 | 219.50 |

THESE GRADIENTS ARE NOT RECOMMENDED

Surface Water Flow Calculation Sheet – click here

Foul Water Flow Calculation Sheet – click here

Combined Flow Calculation Sheet – click here

Conversation Graph. Discharge Units – Flow

Proportional Velocities and Discharges in pipes running part full

| Proportional Depth | Proportion of full-bore values | |

| Velocity | Discharge | |

| 0.02 | 0.128 | 0.001 |

| 0.04 | 0.213 | 0.003 |

| 0.06 | 0.283 | 0.007 |

| 0.08 | 0.345 | 0.013 |

| 0.10 | 0.400 | 0.021 |

| 0.12 | 0.450 | 0.031 |

| 0.14 | 0.496 | 0.042 |

| 0.16 | 0.539 | 0.056 |

| 0.18 | 0.580 | 0.071 |

| 0.20 | 0.618 | 0.088 |

| 0.22 | 0.654 | 0.107 |

| 0.24 | 0.688 | 0.127 |

| 0.26 | 0.720 | 0.149 |

| 0.28 | 0.750 | 0.172 |

| 0.30 | 0.779 | 0.197 |

| 0.35 | 0.846 | 0.264 |

| 0.40 | 0.904 | 0.338 |

| 0.45 | 0.955 | 0.417 |

| 0.50 | 1.000 | 0.500 |

| 0.55 | 1.038 | 0.585 |

| 0.60 | 1.071 | 0.671 |

| 0.65 | 1.097 | 0.755 |

| 0.70 | 1.117 | 0.835 |

| 0.75 | 1.130 | 0.909 |

| 0.80 | 1.136 | 0.974 |

| 0.85 | 1.134 | 1.027 |

| 0.90 | 1.121 | 1.063 |

| 0.95 | 1.092 | 1.072 |